PE PP pelletizer tshuab nqe

Kev piav qhia

Yas pelletizer tshuab yog cov txheej txheem ntawm kev hloov cov yas rau hauv granules. Hauv kev ua haujlwm, cov polymer yaj tau muab faib ua ib lub nplhaib ntawm cov hlua uas ntws los ntawm ib qho annular tuag rau hauv lub txiav chamber dej nyab nrog cov txheej txheem dej. Ib tug rotating txiav lub taub hau nyob rau hauv cov dej ntws txiav cov polymer strands rau hauv pellets, uas yog tam sim ntawd conveyed tawm ntawm lub txiav chamber.

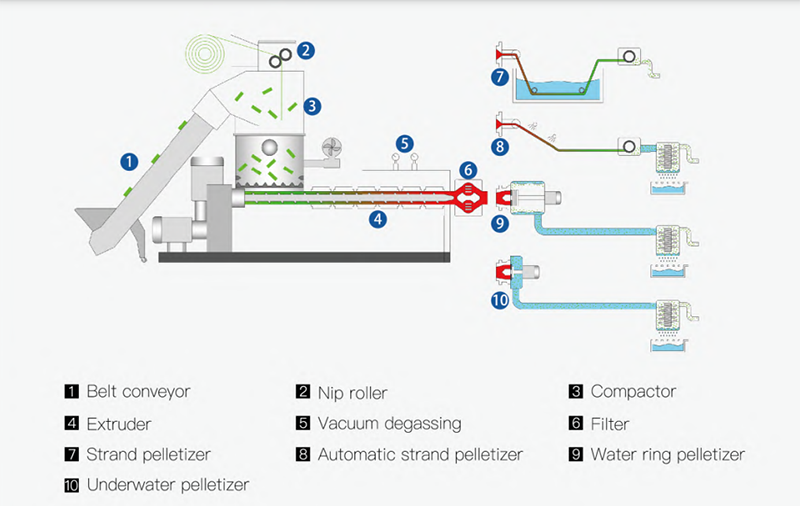

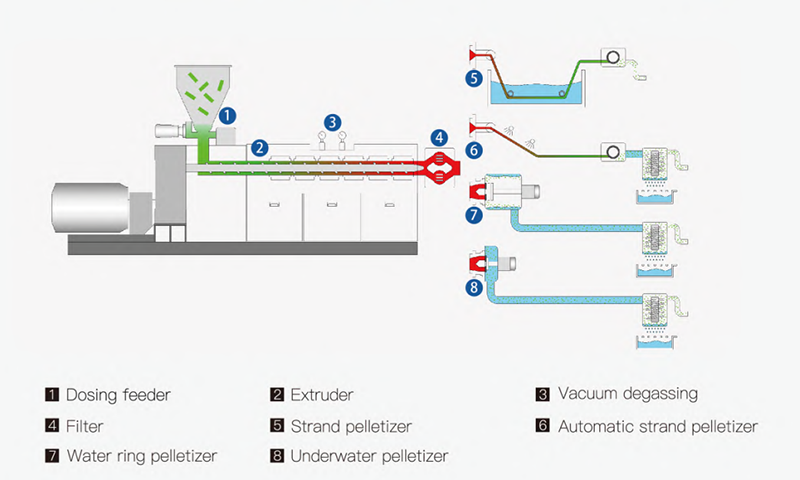

Yas pelletizing cog tuaj yeem kho raws li ib leeg (tsuas yog ib lub tshuab extrusion) thiab ob theem kev npaj (ib lub tshuab extrusion tseem ceeb thiab ib lub tshuab me me thib ob extrusion).

"Hot Cut" dej-ntiv nplhaib tuag ntsej muag pelletizing thiab "Cold Cut" strand pelletizing txoj kev muaj nyob ntawm seb koj nyiam.

Melt pelletizing (kub txiav): Qhuav los ntawm ib tug tuag uas yuav luag tam sim ntawd txiav mus rau hauv pellets uas yog conveyed thiab txias los ntawm cov kua los yog roj;

Strand pelletizing (txias txiav): Qhuav los ntawm lub taub hau tuag yog hloov dua siab tshiab rau hauv cov strands uas raug txiav rau hauv pellets tom qab txias thiab solidification.

Peb tuaj yeem tsim cov tshuab pelletizer zoo rau koj nrog tus nqi zoo pelletizer tshuab.

Paub meej

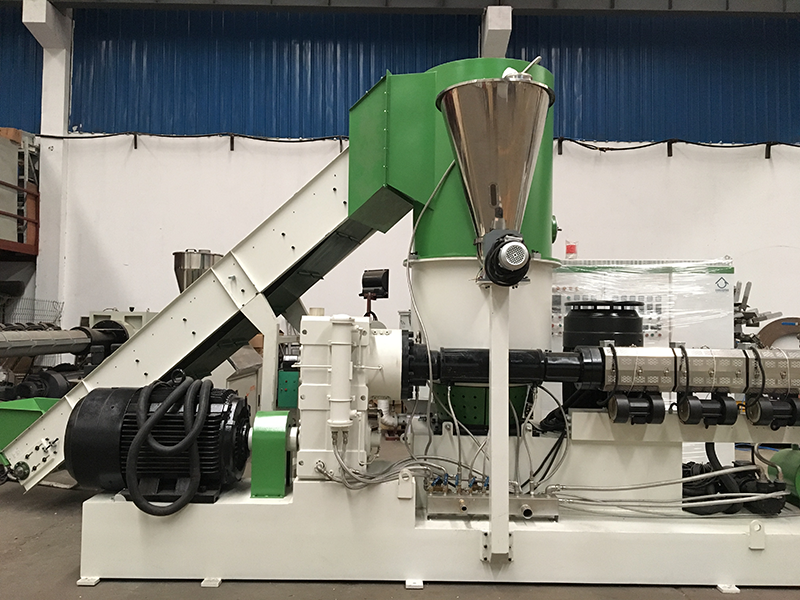

Compactor Unit

Kev sib xyaw ua ke ntawm kev kub ceev rotatory hniav thiab cov hniav nyob ruaj ruaj nrawm nrawm nrawm ntawm kev cog lus thiab coj cov ntaub ntawv mus rau hauv extruder screws.

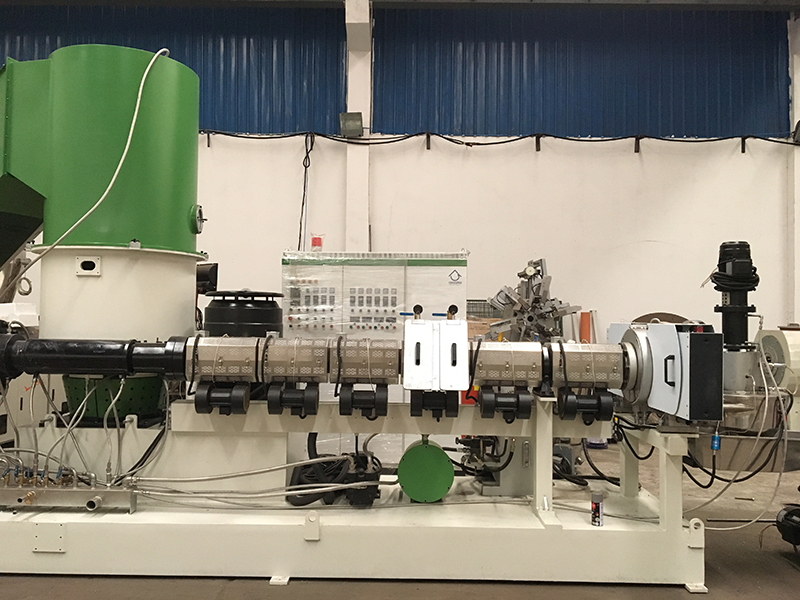

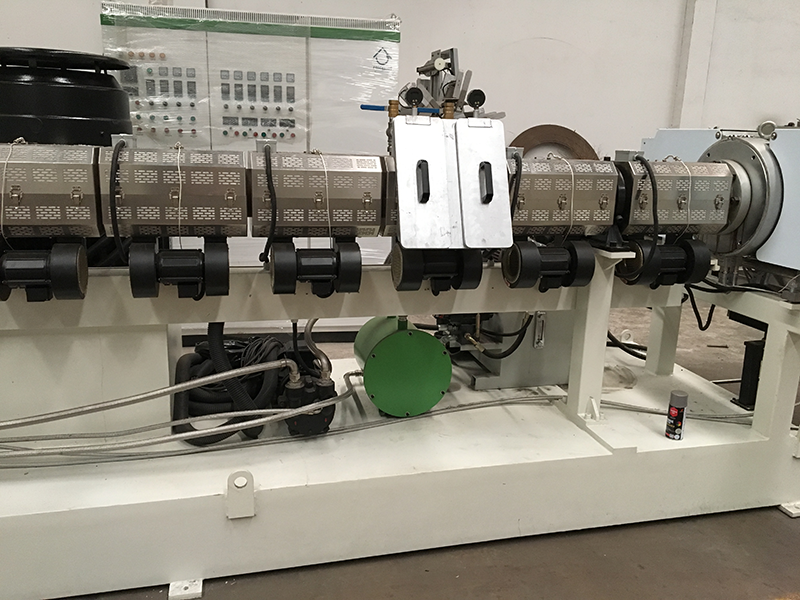

Extruder Unit

Ib qho tshwj xeeb ib leeg ntsia hlau extruder thov kom maj mam yaj cov khoom ua ntej-compacted.

Cov khoom siv yas yuav zoo yaj, plasticized hauv extruder.

High npaum chim thiab ntsia hlau siv rau extruder nrog zoo heev plasticizing tshwm sim thiab siab tso zis muaj peev xwm, txais yuav siab hnav resistant alloy khoom los xyuas kom meej 1.5 lub sij hawm kev pab cuam lub neej ntawm ib txwm ib tug.

Degassing unit

Nrog rau ob lub tshuab nqus tsev degassing, feem ntau cov volatiles tuaj yeem raug tshem tawm tau zoo, tshwj xeeb tshaj yog cov ntawv luam tawm hnyav thiab cov khoom siv nrog qee cov dej.

Lim

Hom phaj, hom pistion thiab tsis siv neeg tu tus kheej hom lim, Kev xaiv sib txawv raws li cov ntsiab lus tsis huv hauv cov khoom siv thiab cov neeg siv khoom tus cwj pwm.

Phaj hom lim yog tus nqi-zoo thiab yooj yim rau kev khiav lag luam uas tsuas yog siv rau cov thermoplastic li niaj zaus

filtration daws.

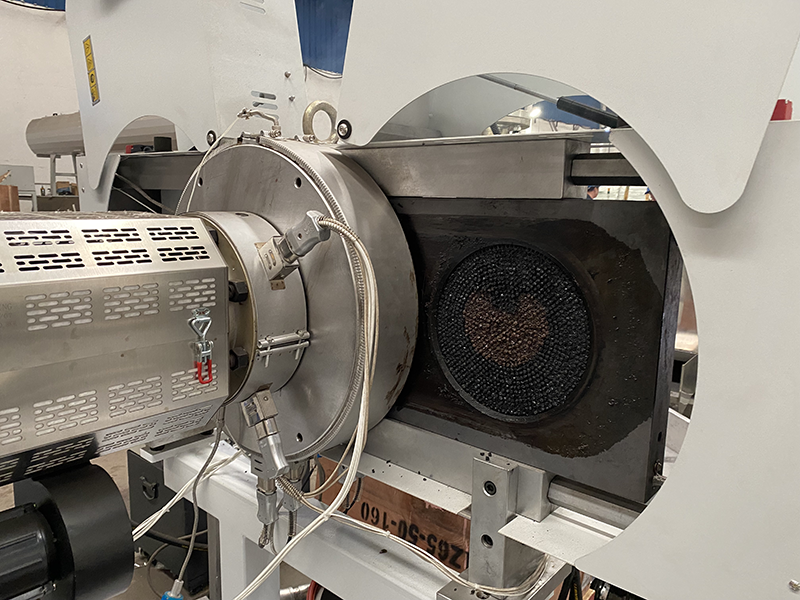

Lub nplhaib dej pelletizer

Kev txiav ceev ntawm pelletizer tswj tau los ntawm PLC raws li lub siab ntawm lub taub hau tuag, uas tuaj yeem ua tiav qhov loj me rau cov zis pellets.

Cov hniav ntawm pelletizer kov kom tuag phaj txiav los ntawm pneumatic system, xyuas kom cov hniav

kev sib cuag nrog cov phaj tuag kom zoo, yooj yim rau kev khiav lag luam thiab tsis muaj kev puas tsuaj.

Technical Data

| Hom | KCP 80 | KCP 100 | KCP 120 | KCP140 | KCP160 | KP180 | |

| Peev xwm (kg / h) | 150-250 | 300-420 : kuv | 400-600 | 600-750 | 800-950 | 1000-1200 Nws | |

| Kev siv hluav taws xob (kWh / kg) | 0.2-0.33 Nws | 0.2-0.33 Nws | 0.2-0.33 Nws | 0.2-0.33 Nws | 0.2-0.33 Nws | 0.2-0.33 Nws | |

| Compactor | Ntim (L) | 300 | 500 | 800 | 1000 | 1200 | 1400 |

| Lub cev muaj zog (kw) | 37-45 : kuv | 55-75 : kuv | 75-90 : kuv | 90-132 : kuv | 132-160 : kuv | 160-185 : kuv | |

| Extruder | Ntsia Hlau Diameter (mm) | ib φ80 | φ100 | φ120 | φ140 | φ160 | φ180 |

| L/D | 30-40 | 30-40 | 30-40 | 30-40 | 30-40 | 30-40 | |

| Lub cev muaj zog (kw) | 55-75 : kuv | 90-110 : kuv | 132-160 : kuv | 160-200 Nws | 250-315 : kuv | 315-355 : kuv | |

| Lim (xaiv) | Ob txoj hauj lwm phaj hom | ● | ● | ● | ● | ● | ● |

| Ob txoj haujlwm piston hom | ○ | ○ | ○ | ○ | ○ | ○ | |

| Back flush piston hom | ○ | ○ | ○ | ○ | ○ | ○ | |

| Tsis siv neeg self-cleaning hom | ○ | ○ | ○ | ○ | ○ | ○ | |

| 2nd Extruder (yeem) | Ntsia Hlau Diameter (mm) | φ100 | φ120 | φ150 | φ150 | φ180 | φ200 |

| L/D | 10-18 | 10-18 | 10-18 | 10-18 | 10-18 | 10-18 | |

| Lub cev muaj zog (kw) | 37-45 : kuv | 45-55 : kuv | 55-75 : kuv | 75-90 : kuv | 90-110 : kuv | 110-160 : kuv | |

| Downstream (kev xaiv) | Lub nplhaib dej pelletizer | ● | ● | ● | ● | ● | ● |

| Strand pelletizer | ○ | ○ | ○ | ○ | ○ | ○ | |

| Tsis siv neeg strand pelletizer | ○ | ○ | ○ | ○ | ○ | ○ | |

| Underwater pelletizer | ○ | ○ | ○ | ○ | ○ | ○ | |

● txheem ○ lwm txoj